Nano-Precipitated Calcium Carbonate: The Silent Revolution Reshaping Industrial Fillers Market

Nano-precipitated calcium carbonate (NPCC) is revolutionizing high-performance fillers, offering superior properties for polymers, packaging, and pharma use.

NEWARK, DE, UNITED STATES, June 10, 2025 /EINPresswire.com/ -- The global calcium carbonate market has long been associated with conventional applications in paper production, plastics, construction, and paints. Ground calcium carbonate (GCC) and precipitated calcium carbonate (PCC) have historically dominated the scene, offering economical and functional fillers for a wide array of industries. Yet, within this mature market, a quiet but powerful shift is underway. Nano-precipitated calcium carbonate (NPCC), a more refined and advanced version of traditional PCC, is carving out a promising niche—transforming the landscape of high-performance fillers and adding new dimensions to material science applications.

Though rarely the centerpiece of calcium carbonate market reports, NPCC is experiencing a subtle surge in attention, particularly from segments that demand enhanced performance and precise engineering. From automotive polymers to high-barrier packaging films and biomedical materials, NPCC is becoming a crucial differentiator for manufacturers seeking value beyond volume.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-3794

𝐔𝐧𝐝𝐞𝐫𝐬𝐭𝐚𝐧𝐝𝐢𝐧𝐠 𝐍𝐚𝐧𝐨-𝐏𝐫𝐞𝐜𝐢𝐩𝐢𝐭𝐚𝐭𝐞𝐝 𝐂𝐚𝐥𝐜𝐢𝐮𝐦 𝐂𝐚𝐫𝐛𝐨𝐧𝐚𝐭𝐞: 𝐖𝐡𝐚𝐭 𝐌𝐚𝐤𝐞𝐬 𝐈𝐭 𝐃𝐢𝐟𝐟𝐞𝐫𝐞𝐧𝐭?

At a fundamental level, NPCC differs from traditional PCC in its ultra-fine particle size—typically less than 100 nanometers—and its controlled crystal morphology. Synthesized through gas-liquid carbonation under specific temperature and pressure conditions, NPCC particles exhibit a high surface area-to-volume ratio, contributing to improved dispersion and interfacial bonding when used in composite materials.

This nano-scale structure offers distinct mechanical and thermal properties that are highly desirable in end-use applications. For instance, when used in polymer matrices, NPCC can enhance tensile strength, stiffness, and heat deflection temperatures far more effectively than its micron-sized counterparts. This capability is especially relevant in sectors such as automotive interior components and consumer electronics, where lightweight, durable materials are in high demand.

Moreover, NPCC particles can be surface-modified with stearic acid, silanes, or other coupling agents, improving compatibility with both hydrophobic and hydrophilic matrices. This level of tunability provides an edge over GCC and PCC, whose broader particle size distribution and irregular shapes limit their adaptability in high-tech applications.

𝐆𝐥𝐨𝐛𝐚𝐥 𝐆𝐫𝐨𝐰𝐭𝐡 𝐇𝐨𝐭𝐬𝐩𝐨𝐭𝐬 𝐚𝐧𝐝 𝐃𝐞𝐦𝐚𝐧𝐝 𝐒𝐮𝐫𝐠𝐞: 𝐀 𝐌𝐚𝐫𝐤𝐞𝐭 𝐢𝐧 𝐭𝐡𝐞 𝐌𝐚𝐤𝐢𝐧𝐠

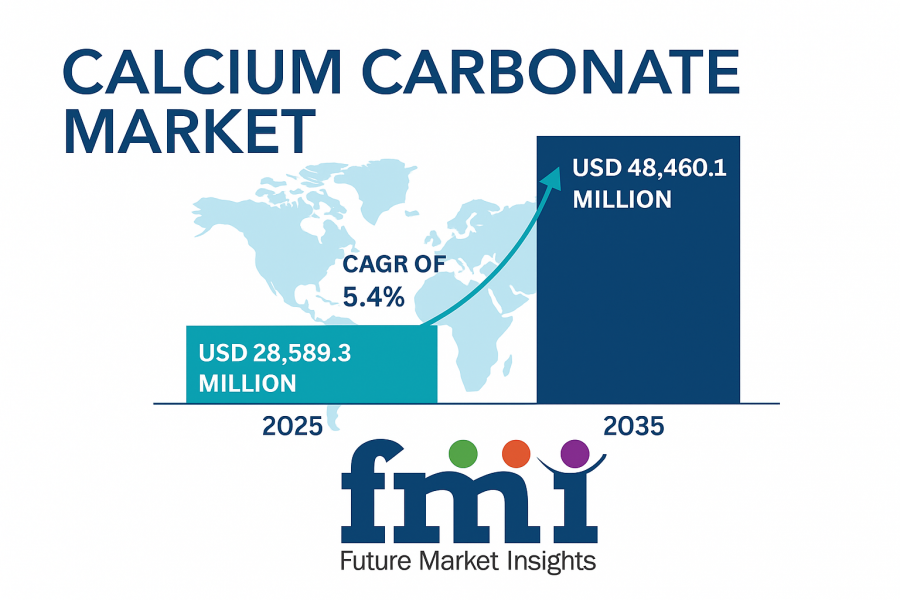

Although the global calcium carbonate market remains dominated by North America and Europe in terms of volume, the growth of NPCC is primarily concentrated in Asia-Pacific. China, in particular, has been a frontrunner in both production and consumption of NPCC, driven by rapid industrialization and a growing demand for advanced plastics and rubber products. According to Future Market Insights, the market is projected to grow from USD 28,589.3 million in 2025 to USD 48,460.1 million by 2035, registering a CAGR of 5.4% during the forecast period.

India is also emerging as a promising market, fueled by infrastructure growth and the government's push toward domestic manufacturing of automotive parts and white goods. Local compounding firms are increasingly incorporating NPCC into polypropylene and polyethylene-based products to reduce weight and enhance product lifespan—attributes that directly contribute to improved fuel efficiency and reduced emissions.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/calcium-carbonate-market

Interestingly, the rising interest in NPCC is also influencing global calcium carbonate price trends. As demand shifts toward value-added products, producers are adjusting their portfolios to include nano grades, leading to a bifurcation in pricing where nano-precipitated variants command a premium, sometimes as much as 40% higher than conventional PCC.

𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧: 𝐅𝐫𝐨𝐦 𝐏𝐨𝐥𝐲𝐦𝐞𝐫𝐬 𝐭𝐨 𝐏𝐡𝐚𝐫𝐦𝐚𝐜𝐞𝐮𝐭𝐢𝐜𝐚𝐥𝐬

One of the most compelling attributes of NPCC is its multifunctionality, which has allowed it to break into industries traditionally untouched by calcium carbonate. In high-performance polymers, NPCC acts not merely as a filler but as a reinforcing agent. Research published in Polymer-Plastics Technology and Materials highlighted that integrating just 3% NPCC into high-density polyethylene (HDPE) improved its tensile strength by 27% and thermal stability by 15%.

In the pharmaceutical sector, NPCC is being evaluated as a carrier for controlled drug release, thanks to its bioactivity and fine particle morphology. Biocompatibility trials at the National University of Singapore showed that nano-calcium carbonate could be used as a pH-sensitive excipient for targeted drug delivery in gastrointestinal therapies. Such applications align NPCC with the broader trend of sustainable and efficient material usage in healthcare, a sector that typically steers clear of bulk fillers like GCC.

Another noteworthy application is in the food packaging industry, where NPCC-enhanced polyethylene films demonstrate significantly improved barrier properties against moisture and oxygen. This development not only extends shelf life but also reduces the need for multilayer packaging structures, thereby supporting circular economy goals.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐚𝐧𝐝 𝐑𝐨𝐚𝐝𝐛𝐥𝐨𝐜𝐤𝐬: 𝐈𝐬 𝐌𝐚𝐬𝐬 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧 𝐚 𝐃𝐢𝐬𝐭𝐚𝐧𝐭 𝐆𝐨𝐚𝐥?

Despite its immense potential, NPCC is not without its limitations. The foremost challenge lies in its production costs, which remain significantly higher due to the energy-intensive and highly controlled precipitation process. Furthermore, achieving consistent particle size distribution at scale remains a technical hurdle, leading to variability in product quality.

Western markets have also shown cautious adoption, largely due to regulatory uncertainties and the absence of well-established health and safety guidelines for nano-scale additives. In contrast, several Chinese manufacturers have addressed these challenges through vertical integration—controlling limestone extraction, calcination, and NPCC production under one umbrella. Companies like ShengdaTech and Jinan Shengquan Group have invested heavily in proprietary surface treatment technologies that not only enhance product performance but also reduce dispersion issues in polymer systems.

𝐈𝐧𝐨𝐫𝐠𝐚𝐧𝐢𝐜 𝐂𝐡𝐞𝐦𝐢𝐜𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/inorganic-chemicals

𝐖𝐡𝐲 𝐍𝐏𝐂𝐂 𝐢𝐬 𝐭𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐅𝐮𝐧𝐜𝐭𝐢𝐨𝐧𝐚𝐥 𝐅𝐢𝐥𝐥𝐞𝐫𝐬

The emergence of nano-precipitated calcium carbonate represents a paradigm shift in the calcium carbonate market, moving the conversation from volume to value. As industries increasingly prioritize high-performance, sustainability, and multifunctionality, NPCC offers a solution that traditional fillers cannot match. Although its path to widespread adoption is not without obstacles, the foundational advantages it offers—from mechanical strength to biocompatibility—position it as a transformational force.

This silent revolution, still underrepresented in most calcium carbonate market reports, is gaining momentum. The industry is no longer just about supplying filler—it’s about engineering function. And in that regard, NPCC is poised to reshape the future of industrial materials.

𝐂𝐚𝐥𝐜𝐢𝐮𝐦 𝐂𝐚𝐫𝐛𝐨𝐧𝐚𝐭𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Product Type:

- Ground Calcium Carbonate (GCC)

- Precipitated Calcium Carbonate (PCC)

By Application:

- Fillers

- Neutralizing Agents

- Construction Materials

- Dietary Supplements

- Desulfurization

- Additive

- Others

By End Use:

- Paper

- Plastic & Rubber

- Paints & Coatings

- Adhesives & Sealants

- Cement & Ceramics

- Agriculture

- Pharmaceuticals

- Others

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Medical Plastics Market: https://www.futuremarketinsights.com/reports/medical-plastics-market

Fire Retardant Coatings Market: https://www.futuremarketinsights.com/reports/fire-retardant-coatings-market

Polyamide Resins Market: https://www.futuremarketinsights.com/reports/polyamide-resins-market

Calcium Carbonate Market: https://www.futuremarketinsights.com/reports/calcium-carbonate-market

Nickel Carbonate Market: https://www.futuremarketinsights.com/reports/nickel-carbonate-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Business & Economy

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release